What Materials Are Commonly Used for Deck Building in St. Louis, MO?

Deck builders in St. Louis, MO know that choosing the right decking material directly determines a deck’s longevity, appearance, and maintenance requirements. Homeowners balancing Missouri’s hot, humid summers with icy winters seek guidance on durable, low-maintenance options for custom decks St. Louis can enjoy year-round. This article explains how climate influences material choice, compares popular woods and synthetics, breaks down costs per square foot, explores railing options, and previews 2025 trends—all to help you partner with a deck builder St. Louis MO trusts for deck installation St. Louis MO calls “perfect.”

You will discover:

Climate-driven performance factors and maintenance challenges

Pros and cons of pressure-treated wood, cedar, redwood, exotic hardwoods

Composite, PVC/vinyl, and aluminum advantages for Missouri conditions

Cost breakdowns, ROI impacts, and local permitting requirements

Railing materials, eco-friendly innovations, and multi-level design trends

What Are the Best Decking Materials for St. Louis’s Climate?

High humidity and temperature extremes demand decking that tolerates moisture without warping, resists mildew, and stands up to freeze-thaw cycles. Materials engineered for moisture resistance and thermal stability outperform traditional wood in St. Louis’s climate.

How Does St. Louis’s Hot, Humid Summers and Cold Winters Affect Deck Material Choice?

Deck performance hinges on thermal expansion, moisture absorption, and freeze-thaw resilience. High summer humidity can cause wood to swell and composite boards to expand marginally, while winter temperature swings lead to contraction and potential cracking. Choosing materials with low water uptake and controlled expansion prevents buckling and splitting, ensuring structural integrity across seasons.

Climate's Impact on Decking Materials

The performance of decking materials is significantly influenced by a region's climate, particularly factors like thermal expansion, moisture absorption, and the freeze-thaw cycle. Materials with low water uptake and controlled expansion are crucial to prevent structural issues such as buckling and splitting, ensuring the deck's integrity across different seasons.

[No Author Listed], Decking Material Selection Guide (2024)

This research highlights the importance of choosing materials that can withstand the specific climate conditions of St. Louis, Missouri.

Which Materials Offer the Best Weather Resistance in St. Louis?

Materials with engineered moisture barriers, UV inhibitors, and rot-resistant composition excel:

Composite decking with capped surfaces repels water and blocks UV-driven fading.

PVC/vinyl boards resist mold, mildew, and freeze damage.

Exotic hardwoods like Ipe feature natural oils that ward off rot and insect attack.

Each option maintains form and color under Missouri’s weather extremes, minimizing warping and discoloration.

What Maintenance Challenges Do Different Deck Materials Face in St. Louis?

Decks vary in upkeep requirements based on porosity and coating:

Pressure-treated wood demands annual sealing and occasional re-staining to prevent moisture infiltration.

Cedar and redwood require periodic oiling to preserve natural oils and prevent graying.

Composite boards need simple deck washing and infrequent mold treatment.

Understanding these demands guides homeowners toward a maintenance regimen that aligns with lifestyle and budget.

What Are the Most Popular Wood Decking Materials in St. Louis?

Wood decking combines classic aesthetics with structural strength, but each species offers distinct durability and care profiles. St. Louis homeowners often choose between affordable pressure-treated pine, visually appealing cedar and redwood, or investment-grade exotic hardwoods.

What Are the Pros and Cons of Pressure-Treated Wood Decks in St. Louis?

Pressure-treated wood is infused with preservatives to resist rot and insects, making it an economical choice. Its affordability and wide availability appeal to budget-conscious projects, but regular sealing and staining are required to maintain appearance and prevent checking under high humidity.

How Do Cedar and Redwood Decks Perform in St. Louis?

Cedar and redwood naturally resist decay thanks to inherent oils. Their warm hues and fine grains deliver aesthetic appeal without chemical treatment, and annual oiling preserves color. However, softwood fibers can dent under heavy furniture and require vigilant cleaning to avoid mildew growth in humid summers.

Why Choose Exotic Hardwoods Like Ipe and Tigerwood for St. Louis Decks?

Exotic hardwoods deliver exceptional durability and minimal maintenance through natural density and oil content. Ipe and Tigerwood resist rot, insects, and fire while retaining shape under temperature swings. Their premium cost is offset by a lifespan exceeding 25 years, making them a solid long-term investment for custom decks St. Louis homeowners cherish.

How Should Wood Decks Be Maintained for Missouri’s Climate?

Wood deck longevity depends on:

Annual inspection for loose boards and fasteners

Biannual cleaning with wood-safe detergents

Reapplication of UV-blocking sealers every 12–24 months

Prompt mildew removal during humid spells

Proactive care prevents structural damage and preserves the natural beauty of wood decking.

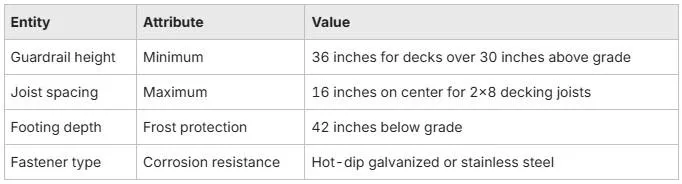

What Are the Local Building Codes for Wood Decks in St. Louis?

Understanding St. Louis building codes ensures safe, compliant construction:

Adhering to these requirements guarantees structural integrity and regulatory approval before deck installation St. Louis MO homeowners schedule.

Why Is Composite Decking a Top Choice for St. Louis Homeowners?

Composite decking blends wood fibers with recycled plastics, creating boards that resist rot, fading, and staining while requiring minimal upkeep. Homeowners benefit from a low-maintenance, long-lasting solution that retains color and texture in Missouri’s climate.

What Is Composite Decking Made Of and How Does It Benefit St. Louis Decks?

Composite decking consists of wood-plastic blend cores with polymer caps that block moisture and UV rays. This composition:

Eliminates splintering and rotting associated with traditional wood.

Provides consistent board dimensions for straightforward installation.

Reduces annual maintenance to simple cleaning, saving time and cost.

Composite Decking Benefits

Composite decking, made from a blend of wood fibers and recycled plastics, offers several advantages, including resistance to rot, fading, and staining. This material choice provides a low-maintenance, long-lasting solution that maintains its color and texture, making it a popular option for homeowners.

[No Author Listed], Composite Decking Advantages (2023)

This information supports the article's discussion on the benefits of composite decking for St. Louis homeowners.

How Do Leading Composite Brands Like Trex, TimberTech, and Fiberon Compare in St. Louis?

Each brand offers robust fade resistance, backed by industry-leading warranties that ensure lasting performance under St. Louis’s sun and humidity.

What Are the Cost and Maintenance Benefits of Composite Decking in St. Louis?

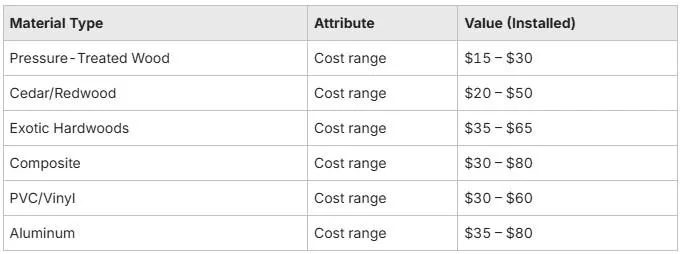

Composite boards cost more upfront than pressure-treated wood—typically $30–$80 per square foot installed—but eliminate annual sealing and staining expenses. Over a 20-year lifespan, savings on maintenance and refinishing offset the higher initial investment, boosting long-term value and ROI for deck builder St. Louis MO projects.

Cost and ROI of Decking Materials

While composite decking has a higher upfront cost compared to pressure-treated wood, the elimination of annual sealing and staining expenses can lead to significant savings over time. Over a 20-year period, the reduced maintenance and refinishing costs can offset the initial investment, increasing the long-term value and return on investment for deck projects.

[No Author Listed], Decking Material Costs and ROI (2023)

This citation provides financial insights into the long-term benefits of choosing composite decking materials.

How Does Composite Decking Resist Fading, Staining, and Rot in Missouri’s Climate?

Polymer cap layers incorporate UV inhibitors and water-repellent additives that:

Block sun-driven color fading

Prevent mold and mildew growth in humid conditions

Eliminate rot by creating an impermeable barrier

This engineered protection ensures composite decks retain their appearance and structure despite Missouri’s weather extremes.

What Are the Advantages of PVC and Vinyl Decking for St. Louis Decks?

PVC and vinyl decking deliver unmatched moisture resistance and low maintenance through fully synthetic construction. Homeowners gain a durable, mold-proof surface that never requires staining or sealing.

How Does Azek PVC Decking Perform in St. Louis Weather?

Azek cellular PVC boards feature foam cores that insulate against heat and cold while resisting moisture absorption. Their engineered surface repels stains and scratches, making them ideal for areas prone to standing water after heavy rains or sprinklers in humid summers.

What Are the Key Differences Between PVC and Composite Decking in St. Louis?

PVC decking is entirely synthetic, eliminating wood content to prevent any risk of rot or insect damage. Composite blends wood fibers with plastic, creating a more natural warmth but requiring careful moisture control. PVC boards tend to cost slightly more—about $30–$60 per square foot—but offer absolute waterproofing and color stability.

Why Are Vinyl Decks Considered Low Maintenance and Durable in St. Louis?

Vinyl boards require only periodic washing to remove dirt and prevent mildew. Their synthetic makeup ensures no warping, splintering, or color loss, even under constant exposure to sun and moisture. This maintenance simplicity appeals to homeowners seeking maximum leisure time over upkeep tasks.

When Should You Consider Aluminum Decking for Your St. Louis Home?

Aluminum decking offers a lightweight, rust-proof alternative that stays cool underfoot and supports modular design options. Its strength and heat-reflective properties make it a compelling choice for modern, low-maintenance decks.

What Are the Benefits of Aluminum Decks in Terms of Weight, Durability, and Heat Resistance?

Aluminum decking panels weigh significantly less than wood or composite boards, simplifying installation and reducing structural load. Anodized or powder-coated finishes resist corrosion and reflect sunlight, keeping deck surfaces cooler and enhancing comfort during hot, humid St. Louis summers.

How Does Aluminum Decking Compare to Wood and Composite in St. Louis?

Aluminum outperforms wood and composite in fire resistance, rot prevention, and insect immunity. While aluminum decking has a higher upfront cost—around $35–$80 per square foot installed—its near-zero maintenance requirements and 50-year lifespan deliver unmatched durability and minimal lifecycle expenses.

How Much Do Deck Building Materials Cost in St. Louis, MO?

Understanding material costs per square foot helps homeowners budget accurately and weigh ROI before committing to a deck installation.

What Is the Average Cost Per Square Foot for Wood, Composite, PVC, and Aluminum Decking?

These figures account for materials, labor, and standard fastening—allowing homeowners to forecast budgets for custom decks St. Louis specialists deliver.

What Factors Influence the Total Deck Building Cost in St. Louis?

Total project cost depends on:

Deck size and complexity (multi-level vs. single-level)

Choice of railing, lighting, and built-in features

Permit fees and local code compliance

Contractor experience and warranty offerings

A clear scope and feature list enable accurate estimates from a reliable deck builder St. Louis MO homeowners recommend.

How Does Material Choice Affect the Return on Investment (ROI) for St. Louis Decks?

Higher-end materials like composite, PVC, and exotic hardwoods often increase resale value and reduce ongoing maintenance expenses. While pressure-treated wood carries lower upfront costs, its required upkeep can diminish ROI over time. Investing in materials with proven durability maximizes property value and lifestyle benefits.

What Are the Best Deck Railing Materials to Complement Decks in St. Louis?

Railings frame your deck’s appearance and safety. Selecting materials that match decking surfaces ensures cohesive design and consistent maintenance demands.

What Are the Benefits of Wood Railings for St. Louis Decks?

Wood railings provide classic styling and can be coordinated with wooden decking boards. They require the same sealing and staining schedule as the deck itself, consolidating maintenance tasks into unified care sessions.

How Do Composite Railings Offer Low Maintenance and Durability?

Composite railing systems feature polymer cap layers that resist fading and moisture. These railings never splinter or rot, matching composite decking aesthetics and simplifying upkeep for a fully integrated system.

Why Choose Aluminum Railings for Modern and Long-Lasting Decks in St. Louis?

Aluminum railings require no painting or sealing, and powder-coated finishes deliver long-lasting color stability. Their slim profiles offer unobstructed sightlines, pairing well with contemporary deck designs and enhancing resale appeal.

What Are the Pros and Cons of Glass and Cable Railings in St. Louis?

Glass and cable railings deliver a sleek, modern look and preserve panoramic views. Glass panels require regular cleaning to remove water spots and pollen, while stainless-steel cable assemblies demand periodic tension checks but otherwise need minimal upkeep.

What Are the Latest Deck Building Trends and Material Innovations in St. Louis for 2025?

Design innovation and sustainable materials are shaping next-generation decks in St. Louis, blending form, function, and eco-responsibility.

How Are Multi-Level Deck Designs Influencing Material Choices in St. Louis?

Multi-level layouts create distinct zones—dining, lounging, grilling—that call for versatile materials. Composite and PVC boards with consistent board widths facilitate seamless transitions between levels, while aluminum framing supports cantilevered decks without bulky posts.

What Sustainable and Eco-Friendly Deck Materials Are Gaining Popularity in St. Louis?

Recycled composite blends and FSC-certified woods reduce environmental impact. Manufacturers are introducing boards made from 90% recycled plastics and reclaimed wood fibers, offering homeowners greener options without sacrificing performance or aesthetics.

How Are Wider Deck Boards and Smart Decking Features Changing St. Louis Decks?

Wider boards create a sleek, contemporary footprint with fewer seams, improving visual flow and reducing cleaning lines. Smart decking innovations—integrated LED lighting, temperature-sensing sensors, and wireless controllers—enhance safety and convenience for evening entertaining.

What Are the Local Regulations and Permits for Deck Building Materials in St. Louis?

Compliance with local codes and permit processes protects homeowners from fines and ensures structural safety.

What Building Codes Affect Deck Material Selection in St. Louis?

St. Louis codes govern:

Guardrail and stair rail height and load requirements

Joist spacing and footing depth for frost protection

Fire separation distances from property lines

Selecting materials and designs that meet these standards prevents costly revisions during inspections.

How Do Local Permits Impact Deck Installation and Material Use?

Securing deck permits involves submitting plans that detail material types, board layouts, and footing details. Permit fees vary by municipality, and failure to comply can result in project delays or mandated removal of non-compliant decks.

Where Can St. Louis Homeowners Find Trusted Deck Builders and Material Suppliers?

Homeowners often turn to local experts with proven track records:

Firms specializing in custom decks St. Louis residents recommend

Established lumberyards and composite distributors in the metro area

Licensed contractors listed with St. Louis County and City building departments

Partnering with reputable deck installation St. Louis MO professionals ensures access to quality materials and code-compliant construction.

Four decades of combined deck-building expertise underscore the importance of material selection tailored to Missouri’s climate, design aspirations, and maintenance preferences. Whether you choose pressure-treated wood, composite, PVC, or aluminum, understanding cost implications and care requirements sets the foundation for a deck that stands the test of time. Partner with a skilled deck builder St. Louis MO homeowners trust to transform these insights into a durable, beautiful outdoor living space. Reach out today to explore materials and design options for your perfect St. Louis deck.

Reliable, professional Deck Builder in St. Charles, MO

Links

Home

Locations

HomeScape Contracting LLC

416 Longbow Trail, Saint Charles MO 63301

314-912-4770

Call Us Anytime!

Monday: Open 24hrs

Tuesday: Open 24hrs

Wednesday: Open 24hrs

Thursday: Open 24hrs

Friday: Open 24hrs

Saturday: Open 24hrs

Sunday: Open 24hrs

Copyright HomeScape Contracting LLC 2025. All rights reserved